Magnetic Particle Testing (Yoke & Prod Technique)

Magnetic Particle Testing (Yoke & Prod Technique)

As per ASME Section V Article 7; by ASNT Level II Technician.

Magnetic particle examination (MT) is a very popular, low-cost method to perform non-destructive examination (NDE) of ferromagnetic material. Ferromagnetic is defined in ASME Section V as “a term applied to materials that can be magnetized or strongly attracted by a magnetic field.” MT is an NDE method that checks for surface discontinuities but can also reveal discontinuities slightly below the surface

How Magnetic Particle Examination Works

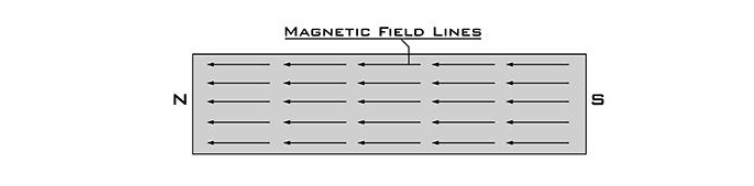

When ferromagnetic material (typically iron or steel) is defect-free, it will transfer lines of magnetic flux (field) through the material without any interruption.

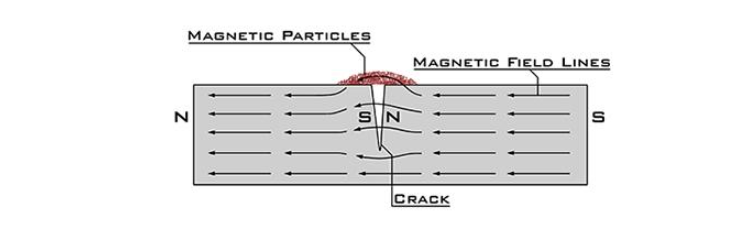

But when a crack or other discontinuity is present, the magnetic flux leaks out of the material. As it leaks, magnetic flux (magnetic field) will collect ferromagnetic particles (iron powder), making the size and shape of the discontinuity easily visible.

However, the magnetic flux will only leak out of the material if the discontinuity is generally perpendicular to its flow. If the discontinuity, such as a crack, is parallel to the lines of magnetic flux, there will be no leakage and therefore no indication observed. To resolve this issue, each area needs to be examined twice. The second examination needs to be perpendicular to the first so discontinuities in any direction are detected. The examiner must ensure that enough overlap of areas of magnetic flux is maintained throughout the examination process so discontinuities are not missed.